At GAS-SYSTEMS, we believe that our innovation and constantly improved products, together with the approach assuming

the care of each implementation of the controlled atmosphere technology, will translate into your measurable success.

Our commitment is reflected in maintaining the excellent quality of our customers' collections throughout the entire storage period.

In our company, we design, manufacture and implement comprehensive installations of a controlled atmosphere for the storage of fruit and vegetables. Our devices are energy-saving, durable, made with attention to the smallest details, which makes them probably the best that can be purchased on the European market.

The solutions we implement are designed to make your work as easy as possible.

Our devices are characterized by a high level of technological advancement, which is reflected, among others, in the developed possibilities of communicating with the user. The GSP CO2 scrubbers (coal scrubbers) produced by us use GSM technology and can be connected to the network using Wifi and Ethernet. They send SMS and email messages and communicate with an external server, improving the remote service capabilities. Specially selected activated carbon based on coconut shells ensures many years of work with the highest efficiency. The design solutions used, incl. the disc air distribution system allows you to work with ultra-low oxygen concentrations, thanks to the precise removal of oxygen from the bed after the regeneration phase.

The GSG nitrogen generators we offer work in energy-saving VPSA technology. We use oil-free compressors in them, which allow us to extend the life of the molecular sieve bed by up to 100% compared to the high-pressure technology (PSA). Our devices have been designed to facilitate their transport as much as possible. The height of the basic models is only 165 cm!

Konrad Puławski

Generators

GeneratorsNitrogen generators are used to quickly lower the oxygen concentration in the KA storage chambers after loading and after each opening. The process consists in replacing the oxygen inside with nitrogen obtained from the atmospheric air.

In the VPSA (vacuum pressure swing adsorption) technology, in which our devices operate, we use low air pressure to separate nitrogen and negative pressure to regenerate the deposits from oxygen captured by them.

It is the most energy-saving technology that generates the lowest operating costs. Additionally, the use of the recirculation mode shortens the chamber gassing time by approx. 30%.

Why should you choose a Gas-Systems nitrogen generator?

| Type | Dimensions (W x L x H) | Efficiency Nm3/h | Power consumption kW |

|---|---|---|---|

| GSG15 | 1000x1300x1640 | 15 | 2,6 kW |

| GSG20 | 1080x1300x1640 | 21 | 4,05 kW |

| GSG28 | 1080x1340x1640 | 28 | 5,2 kW |

| GSG40 | 1080x1400x1840 | 40 | 11,5 kW |

| GSG60 | 1180x1500x1840 | 60 | 12,5 kW |

Scrubbers

ScrubbersIn the process of breathing, fruits and vegetables consume oxygen and produce carbon dioxide at the same time. In the conditions of a cold store with a controlled atmosphere, efforts are made to maintain a stable gas composition at levels that slow down the maturation processes. CO2 washers are designed to remove carbon dioxide from storage chambers, the excessive concentration of which may lead to irreversible damage to fruit and vegetables. It is equally important to control and prevent the oxygen concentration from falling below the setpoints. Although lowering it slows down the respiration process, too low values start the process of anaerobic respiration (fermentation).

Due to the large differences in the amount of carbon dioxide released between different types of fruit and vegetables, the selection of the device's capacity is an individual matter determined after consultation with the customer.

GSP-2 series CO2 scrubbers are designed, in particular, to work in large facilities of individual customers and groups of fruit producers.

Why should you choose a Gas-Systems CO2 scrubber?

| Type | Dimensions (W x L x H) | Handled tonnage* | Power consumption kW |

|---|---|---|---|

| GSP 300 | 780 x 1200 x 1890 | 300 | 1,6 kW |

| GSP 500 | 780 x 1200 x 1940 | 500 | 2,2 kW |

| GSP 700 | 880 x 1300 x 1940 | 700 | 2,2 kW |

| GSP 900 | 980 x 1485 x 1940 | 900 | 2,2* kW |

| GSP 1400 | 1675 x 1085 x 1700 | 1400 | 6,2 kW |

| GSP 2000 | 1775 x 1085 x 1700 | 2000 | 6,2 kW |

* Approximate serviced tonnage of apples for the parameters O2 -2%, CO2 - 2%, temperature 1°C

Soft fruit due to their characteristics require special care and dedicated solutions in the field of storage.

Controlled atmosphere technology gives great results in terms of maintaining freshness and high quality of the product in the long term. It allows you to better spread the supply of fruit over time and effectively manage sales. All this translates into much better financial results of producers using these technologies.

Especially for these purposes, GAS-SYSTEMS has developed a dedicated solution called GasBerry System . It allows you to store fruit on single pallets covered with a special, gas-tight foil. The biggest advantage is the ability to attach and detach pallets at any time. This allows us to obtain maximum distribution flexibility combined with all the benefits of Controlled Atmosphere Technology.

The system developed by us assumes grouping of pallets. Thanks to this, we can maintain a different composition of the atmosphere in them, which in turn allows for the simultaneous storage of several species of fruit in optimal conditions.

Handheld gauge GSA-PRO

Handheld gauge GSA-PROHandheld oxygen and carbon dioxide meters are essential wherever we are dealing with techniques to extend the freshness of products using a controlled or modified atmosphere. They are used for the temporary control of gas concentration in storage chambers, gas-tight pallets or MAP packages.

The GSA-PRO meter, thanks to the use of the highest quality components, is characterized by exceptional durability and measurement precision. It is possible to extend the temperature measurement with an external probe. It has a built-in memory for storing measurements from up to 20 chambers.

| Description | Value |

|---|---|

| Measurement range: | 0-25% O2 i (0-5% CO2 lub 0-20% CO2) |

| Type of sensors: | CO2 – NDIR, O2 – electrochemical |

| Accuracy of measurement: | +/- 5% of the measured value |

| Power - battery | battery operated 2x (3,7V; 18600mAh) |

| Working range (temp.) | 5 - 30 oC |

The compensation bag is used to eliminate changes in pressure inside the storage chamber, which allows to maintain low oxygen concentrations during the storage period.

The portable O2 / CO2 analyzer is used to control the composition of the atmosphere in storage chambers, mushroom farms, and wherever precise information about the composition of the tested gas is needed

The micromanometer is a device used to monitor the pressure differences arising in the storage chamber. It is also helpful in checking the gas tightness class of the chamber.

The decompression valve (wet) protects the storage chamber against damage in the event of a high pressure difference between it and the environment. At the same time, it guarantees tightness.

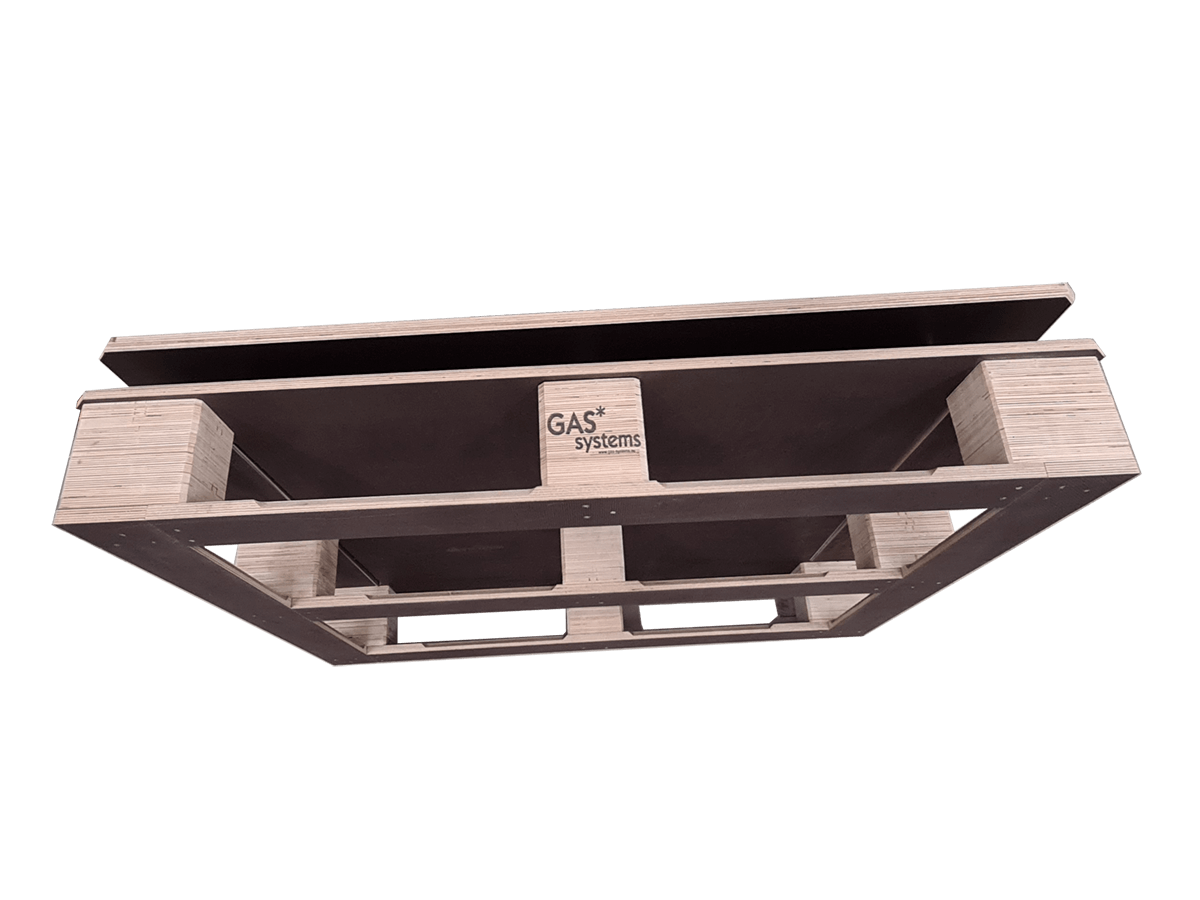

Gas-tight pallets for the GasBerry system

Gas-tight pallets for the GasBerry systemGas-tight pallets for the GasBerry system.